About Us

Who We Are?

We are a fully integrated packaging solution provider in the field of Indian flexible packaging sector. We are committed to the research and innovation of sustainable flexible packaging. Established in 2009, today, Siddhee Products has become synonymous with packaging, covering every conceivable field with an array of advanced paper, film and foil-based laminates with style and imagination.

Our Reputation

done_all Leaders in Wide Web Holography films & registered Holography Laminates.

done_all Leaders in bio-degradable, eco-friendly paper-based barrier laminates

done_all First to introduce Low-cost printable, metallizable grade of Cast Polypropylene (CPP).

done_all Among the first to introduce Polyolefin plastomers (POP) & Metallocene in India.

Our Values

Quality

At our core, we uphold an unwavering commitment to the excellence of our products and services, steadfastly refusing to compromise on quality.Integrity

We are committed to being ethical, honest, and straightforward in all of our actions.Transparency

We prioritize openness and transparency in our interactions with employees, partners, and customers, fostering trust and collaboration at every level.Collaboration

We are open to working with like-minded organizations that share similar values.Leadership Culture

We endeavor to cultivate a culture of ownership and leadership within both our teams and organization. Rooted in trust, support, and the freedom to innovate, our culture encourages exploration and fosters limitless possibilities.Innovation & Expansion

At the forefront of our priorities lie innovation and growth, as we continuously seek avenues for enhancement and advancement through cutting-edge technology. Our unwavering dedication is to craft packaging solutions that garner global recognition.

Snapshot

done_all Established in 2005; an industry presence with edge as we produce our own CPP.

done_all A pioneer in packaging industry, offering quality solutions in flexible packaging including security packaging.

done_all Headquartered in Mumbai and having state-of-the-art manufacturing locations in Umbergaon, Gujarat.

done_all An established customer base across the industry spectrum.

done_all Close proximity to the major raw material and consumption centers.

done_all Foraying into Export with clients of very high repute in UK, Europe & Africa.

done_all 250 employees across, a highly qualified R & D and product development team.

What makes flexible packaging attractive?

done_all Materials like metal and glass are becoming increasingly expensive.

done_all Great opportunities for outsourcing to emerging nations.

done_all High barrier, High performance pouches are also becoming stronger players in seafood, rice, wet pet food, and ready to eat meal and QSR (Quick Service Restaurant) applications.

done_all Changing Consumer habits within 1,2 & 3 Tier cities with fast growing working middle class consumer segment.

Thus, impetus given on easy, fast, convenient, and flexible products, which is the prime deliverance of FLEXIBLE PACKAGING.

Major demand drivers for flexible packaging

done_all Quality consciousness amongst buyers

done_all Promising economic growth & Increasing purchasing power.

done_all Deeper market penetration due to Unit pricing policy followed by FMCG Cos & MNCs.

done_all The emergence of newer market segments such as ready-to-eat fast food in flexible packages.

done_all Accelerated growth of rural economy with tilt towards branded packed products.

done_all Rampant growth in online shopping is likely to give further impetus to packaging industry.

The Indian flexible packaging industry is gaining global competitiveness for several reasons:

Cost Efficiency

India offers significant cost advantages due to lower labor costs, affordable raw materials, and efficient production processes. This cost efficiency enables Indian manufacturers to offer high-quality packaging solutions at competitive prices, attracting global clients seeking value for money.Technological Advancements

The industry has embraced cutting-edge technologies and automation, enhancing production capabilities and quality standards.Skilled Workforce

India has a large pool of skilled professionals and technicians with expertise in flexible packaging.Strong Domestic Market

The robust domestic market provides a solid foundation for the industry, allowing manufacturers to achieve economies of scale. The growing demand for packaged goods in India fuels innovation and capacity expansion, positioning Indian companies to better compete in international markets.Government Support and Policies

Favorable government policies, including incentives for export-oriented units, infrastructure development, and ease of doing business initiatives, have bolstered the industry's global competitiveness.

Where are we headed to

done_all Several capital expenditures have been executed and finalized in recent years. The collective result has yielded a converting capacity exceeding 20,000 metric tons annually.

done_all Upcoming Greenfield projects are currently in the planning stages across various locations, strategically aimed at enhancing client accessibility and implementing a usage-based purchasing model to streamline inventory management for our clientele.

done_all Exploring avenues for outsourcing flexible packaging needs from leading global entities, aiming to assist them in achieving cost-effective, high-quality materials. Additionally, facilitating the application process for elevated standards such as BRC-IOP to ensure adherence to superior manufacturing practices.

done_all Establishing a reputation as a premier provider of packaging solutions both domestically and internationally, by offering a diverse range of services to expand our client base.

done_all Attain self-sufficiency through the cultivation of a distinctive work culture model that systematically reinforces all aspects of our growth strategy. This approach aligns with our overarching objective of fostering a sustainable, profitable, growth oriented, technologically adept, socially conscious, and forward-thinking organization

Our Journey Brick by Brick

Manufacturing Competence

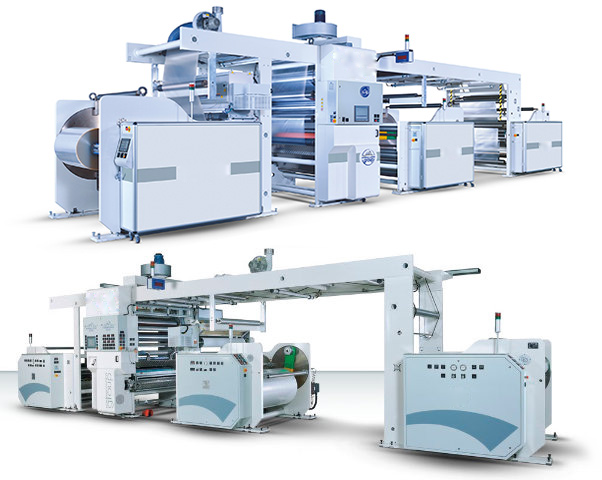

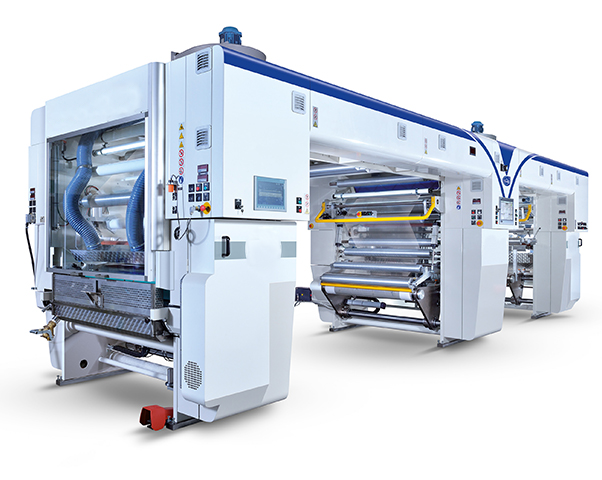

done_all Printing facilities for up to 10 colors of European makes with Rotogravure & Flexo technology.

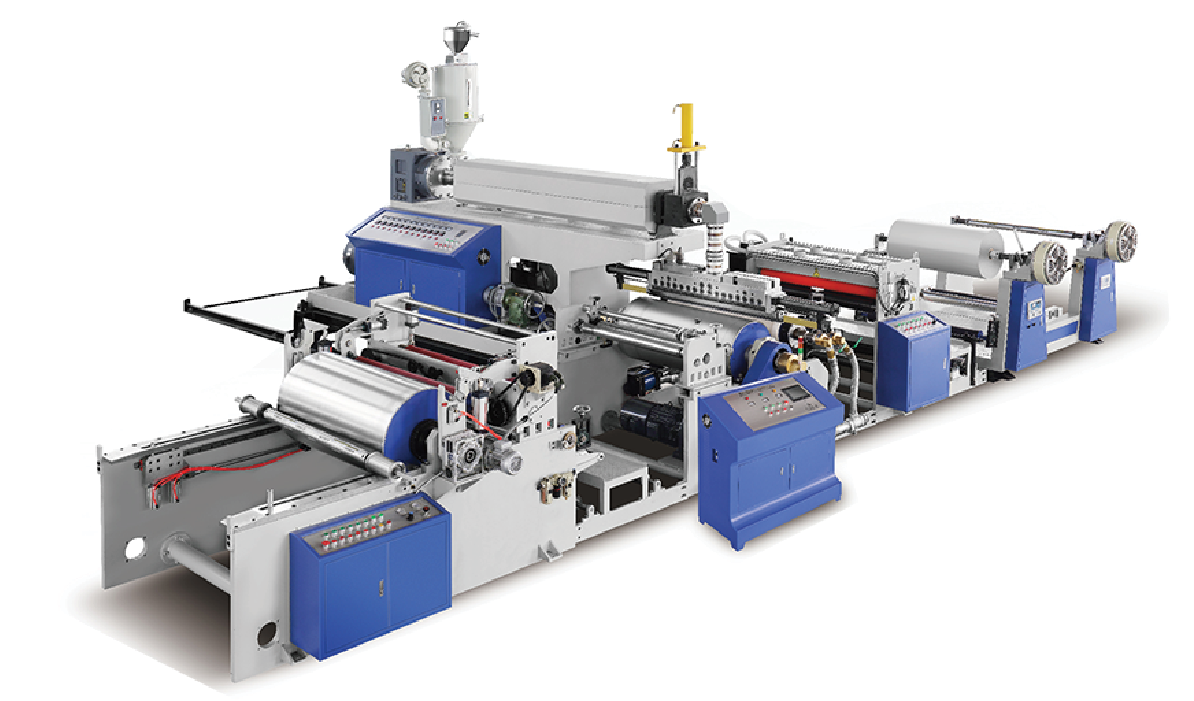

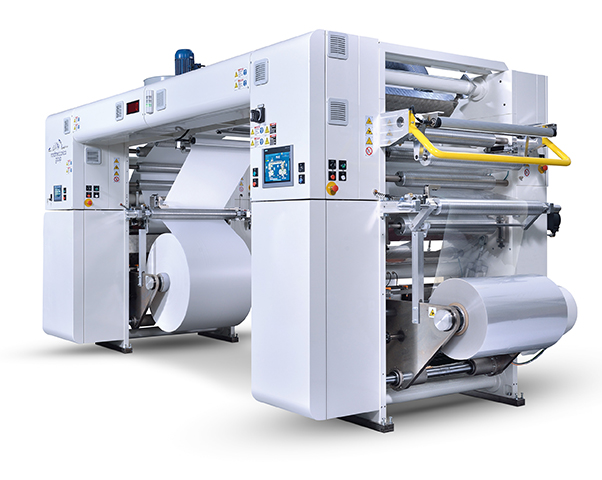

done_all Lamination and specialized coating systems with Solvent based, Solvent less, water-based Lamination technologies.

done_all Multilayer Extrusion facilities in Cast (CPP, EVOH, EVA) & blown technologies.

done_all Advanced Holographic plant from Italy with Hot & Cold foil embossing machines

done_all High Speed Slitters in various numbers from different origins.

done_all Accurate flatbed stamping foil & rotary hot foiling technology

120

Happy Clients

200

Projects

20

Years of Experience

3

Awards